Willard Says……

CONVAC The key to maximum production

Introduction

The following questions and answers reveal how hydraulic dredge users can use a truly productive bypass valve system—CONVAC—to achieve and maintain the maximum possible rate of solids production. Also, it explains why utmost dredge performance is impossible without CONVAC.

The cost to own, man and power a dredge system that is pumping only clear water is quite substantial. When solids are introduced into the flow, energy and maintenance costs increase moderately, but only in proportion to the density of the slurry. That means the lowest per-ton production cost results when high-density slurry is pumped through the system without interruption. CONVAC makes that possible.

Many dredge owners load out their products with end loaders. If they see a particular machine making extra passes with a half-full bucket they quickly take steps to remedy that problem. Should not the same concern for maintaining high-capacity performance also apply to their dredge? Why tolerate half-capacity dredge performance when a CONVAC system would make it easy to continually “fill its bucket?”

CONVAC is a Twinkle Co creation. All software programming, hardware design, fabrication, assembly, component and system testing, sales and service originates exclusively at Twinkle Co’s Iowa facility.

As always, Twinkle Co continues its relentless search for ways to improve the performance and reliability of the CONVAC system.

FORWARD

Years ago I traveled a great deal seeking access to all the sand and gravel dredges I could find. My goal was to convince dredge owners that Twinkle Co could be of service to them. At the time, few dredges were equipped with velocity meters which gave me the opportunity to install my portable unit and demonstrate the virtues the instrument before their very eyes.

With a little coaching owners could watch their operators increase production 25 to 50 percent or more. They did not have to believe my salesman’s pitch with its promise of wondrous good things to come. They could see it actually happening. They could watch as the normal, intermittent stream of sand falling off the belt become a continuous, heavy stream. And as they watched, enjoy the pleasant prospect of increased profits.

As I installed more velocity meters and had the opportunity to watch an increasing number dredges of all types and sizes in operation, I conceived Dredging Principle #1. Repeated trials always validated the concept.

DREDGING PRINCIPLE #1

“A constant rate of solids production results when pump speed and Setpoint Velocity are held constant.”

This principle requires that two variables be held constant. Holding pump speed constant is a matter of setting and forgetting the throttle. But how in the heck does one control velocity when the meter shows it to be wandering around quite a lot? The search for the answer to that question led to Dredging Principle #2.

DREDGING PRINCIPLE #2

“With pump speed fixed, Setpoint Velocity can be held constant by adjusting Setpoint Vacuum.”

And how is that done? The same old way, by maneuvering the suction inlet, but with a big difference. That difference is the guidance provided by the velocity meter that indicates when, up or down and how much the Setpoint Vacuum should be tweaked to maintain Setpoint Velocity.

Finally, Dredging Principle #3 explains how achieve the ultimate goal: maximize the rate of solids production.

DREDGING PRINCIPLE #3

“To increase the rate of production, increase pump speed and maintain Setpoint Velocity.”

Q# TITLE

2 What does a bypass valve do?

5 What is a Linear Needle Valve?

6 What principles govern CONVAC’s function?

7 Who needs a CONVAC system on their dredge?

8 What will change after CONVAC is installed?

9 What limits the rate of solids production?

10 What constitutes a CONVAC system?

11 What is the warranty on CONVAC?

12 CONVAC seems expensive. How will I get my money back?

13 What other instruments and controls are available?

14 What makes CONVAC superior to other systems?

Q1 What is vacuum?

A Vacuum, 1. The absence of matter, 2. An empty area or space.

As applied to hydraulic dredging, vacuum is a differential pressure, the low pressure inside the pump suction compared to the higher pressure outside the suction inlet.

An operating hydraulic dredge pump creates vacuum—an area of low pressure—inside its suction port. Slurry outside the suction pipe, being subject to higher pressure, obeys the laws of physics and flows toward the area of lower pressure—the suction inlet. Such is the continuous process that makes hydraulic dredging possible.

Hullpumps located above water use a conventional 0-30 inHg gauge to measure differential pressure, the reduced pressure inside the pump relative to the atmospheric pressure outside.

Ladderpump dredges require a Twinkle Co LADDERVAC, a rather sophisticated instrument, to measure the differential between the varying lower pressure inside and the varying higher pressure outside the immersed pump suction inlet.

Modern dredges use electronic transducers to sense pressures of all kinds. The digital vacuum signal is fed into automation software programs. Automation such as CONVAC.

Using the velocity indicator as reference, the operator can maintain Setpoint Velocity by making slight adjustments—tweaking—the Setpoint Vacuum.

Setpoint Vacuum and Setpoint Velocity are values to be entered in the appropriate boxes on the CONVAC display by the operator.

Causing vacuum to increase by maneuvering the suction inlet generally results in an increase in the rate at which solids enter the suction inlet. Likewise, a spontaneous increase in vacuum, perhaps caused by a cave-in, signals an increase in the rate of solids intake. A decrease in vacuum, whether intentional or spontaneous, indicates a decreasing rate of solids intake due to a diminishing supply of pumpable solids near the suction inlet.

NOTE; Maintaining a steady vacuum will not result in a steady rate of of solids intake.

The goal should be to regulate and maintain the rate at which solids enter the dredge system close to the maximum possible rate that can be pumped to the discharge point. As will be explained further on, the key to regulating the rate at which solids enter the dredge system is to maintain Setpoint Velocity while running the pump at a fixed speed. Setpoint Velocity regulation is accomplished by adjusting Setpoint Vacuum

Controlling vacuum should be viewed as key to regulating or maximizing production.

Q2 What does a bypass valve do?

A The Willardsays paper, “Suction Bypass Valves”, provides most of the answers along with some historical background and a schematic showing one installed.

In the 1930’s bypass valves were offered to provide fast relief from pump cavitation which resulted from suction choke-off, i.e. cave-ins. Attempts to use a bypass valve as a means of automating the rate of solids production first came to my attention in the early 1980’s.

At that time, several inventive chaps including this writer were devising and installing contraptions on dredge suction pipes with the goal of helping operators increase production.

Ingenuous tho they may have been, none of these early bypass valve systems turned out to be even moderately successful in increasing production. Some actually interfered with production. As one dredger put it me, “When the valve goes open the belt goes empty!”

The problems were twofold:

-

-

- Students of the art of dredging did not fully understand how the laws of physics apply to goings on in the suction pipe or, indeed the whole dredge system.

- Electronics were not yet readily available for use in controlling dredge operation.

-

Today, CONVAC automates much of the operator’s task. It does not eliminate his job but does relieve much of the boredom, stress and strain that previously afflicted those who were conscientious about their work. CONVAC makes it possible to produce solids continuously at rates previously unheard of. See below.

Q3 What is CONVAC?

A Twinkle Co’s CONVAC modulating bypass valve system enables the dredge operator to;

-

-

-

- Select and adjust the Setpoint Vacuum.

- Select and maintain Setpoint Velocity.

- Diminish or eliminate pump cavitation.

- Guard against pipeline plugging.

- Regulate or maximize the rate of solids production.

- Minimize the per-ton cost of production.

- Be more productive, work less.

-

-

CONVAC stands for CONtrolled VACuum which as explained in Q1 is key to maintaining Setpoint Velocity, the vital ingredient required to regulate and control the rate of solids production.

Q4 What does “modulate” mean?

A Modulate, “to adjust or to keep in proper proportion.”

Early bypass systems featured quarter-turn, or butterfly valves mounted directly on the suction pipe. They slammed open quickly in an attempt to forestall the onset of cavitation or at least mitigate its effects. Most valves sold today retain, to their detriment, elements of that defective procedure. CONVAC’s proprietary Linear Needle Valve, by way of contrast, responds in a manner appropriate to the situation.

A slight rise above Setpoint Vacuum is corrected by allowing entry just enough water to cause vacuum to return to the setpoint. A greater excursion above the Setpoint Vacuum will trigger the entry of a greater flow, but again, only as much as is required to cause a return to Setpoint Vacuum.

Note; A decrease in vacuum below the Setpoint cannot be corrected by CONVAC because that is an indication that an adequate supply of pumpable solids is no longer available at the suction inlet. CONVAC cannot inject solids into the suction pipe, it is designed to cope with an over-supply of pumpable solids.

That said, CONVAC offers a simple solution to the problem of low vacuum. As soon as the Linear Needle Valve goes shut, crowd the cutter into the material bank to assure that an adequate supply of pumpable solids is constantly available at the suction inlet. CONVAC is designed to operate constantly.

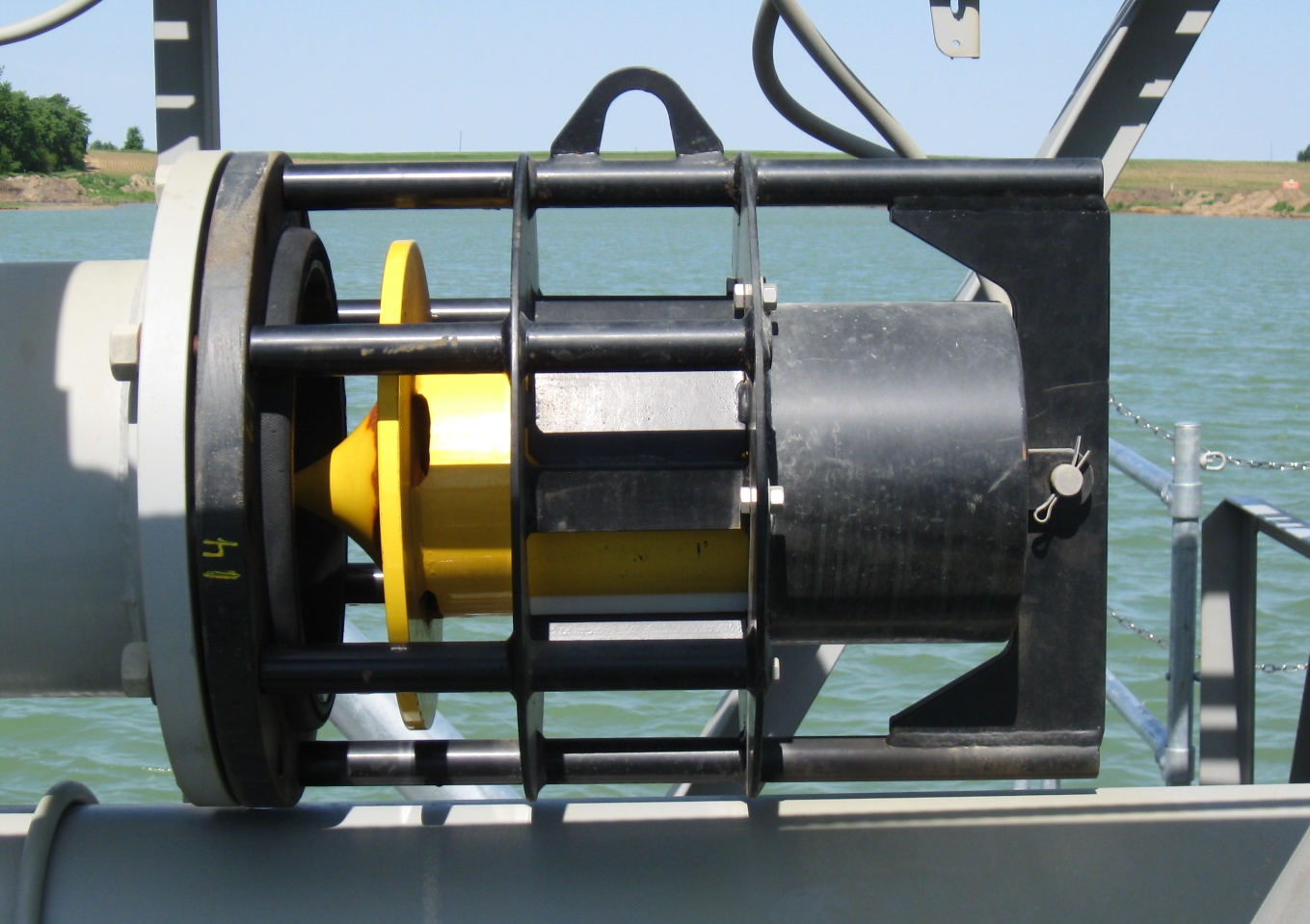

Q5 What is a Linear Needle Valve?

A Water is admitted into the CONVAC bypass pipe through a specially designed needle valve we call a Linear Needle Valve. The valve is very efficient from a hydraulic perspective, an important consideration because the pressure differential that causes water to flow through the valve is quite low at times.

The valve is hydraulically actuated and its exact, real time position is displayed on the CONVAC control panel. Various valve operating parameters can be entered to customize valve response so that best performance is assured even in unique dredging situations.

Q6 What principles govern the function of CONVAC?

A They are three in number. See FORWARD above. CONVAC largely automates the goal of maintaining Setpoint Velocity.

Q7 Who needs a CONVAC system on their dredge?

A Anyone who wants to utilize their dredge system to its full potential, achieve and maintain a very high rate of solids production, reap the benefits of efficient operation and enjoy the lowest per-ton operating cost.

Q8 What changes after CONVAC is installed?

A Imagine:

-

-

-

- That the operator’s job has been reduced to tweaking the setpoint vacuum and crowding the cutter into the bank to maintain an excess supply of pumpable solids at the suction inlet.

- No more time lost spent trying to increase vacuum to maintain production.

- The increase in production because the operator will not have to raise the suction inlet each time there is a threat of pipeline plugging or suction choke-off.

- How production will increase because the operator can hold Setpoint Velocity continuously.

- That the threat of pipeline plugging goes away.

- How specification product yield and quality will increase when the process plant is fed a uniform, constant flow of high-density slurry.

-

-

Q9 What limits a dredge’s rate of solids production?

A A dredge’s maximum rate of solids production depends to great extent on which factor limits its capability;

-

-

- Discharge-side limited means that the rate of solids production is limited to the rate at which they can moved to discharge. Maximum production is achieved by adjusting the Setpoint Vacuum as necessary to maintain the Setpoint Velocity with the pump running at maximum speed.

- Suction-side limited means that production is limited by the rate at which solids can be raised to the pump inlet without causing cavitation. Best production is obtained by adjusting the pump speed so that the Setpoint Velocity can be maintained by adjusting the Setpoint Vacuum as high as possible without causing cavitation. If cavitation occurs, reduce the pump speed.

- Process-plant limited means that the rate of solids production cannot exceed the capacity of the process plant. Regulated production is obtained by maintaining the Setpoint Velocity by adjusting the Setpoint Vacuum and adjusting pump speed until the rate of production matches plant capacity.

- Excess solids limited. Best production is obtained by operating the dredge in the manner appropriate to one of the categories described above, If, however, a continuous supply of excess solids cannot be maintained at the suction inlet CONVAC will no longer control production. Consider installing a more effective cutter or placer jets near the suction inlet or both.

-

Higher velocity will cause a substantial increase in the flow going into a process plant which can be avoided by reducing the pump speed as necessary to maintain flow at a lower Velocity Setpoint.

CONVAC’s available VEECON system automatically adjusts pump speed to maintain Setpoint Velocity. The rate of solids production will vary with pump speed.

When sufficient solids become available, normal pump speed should be restored and Setpoint Vacuum regulation of Setpoint Velocity resumed.

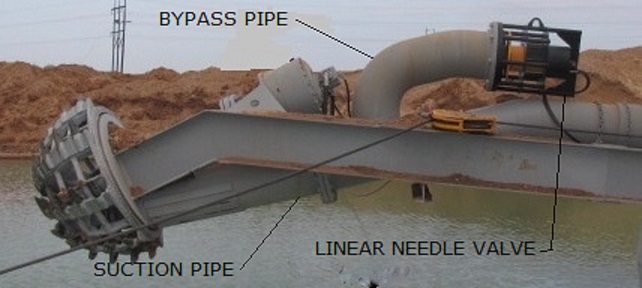

TYPICAL CONVAC SYSTEM

Figure 1

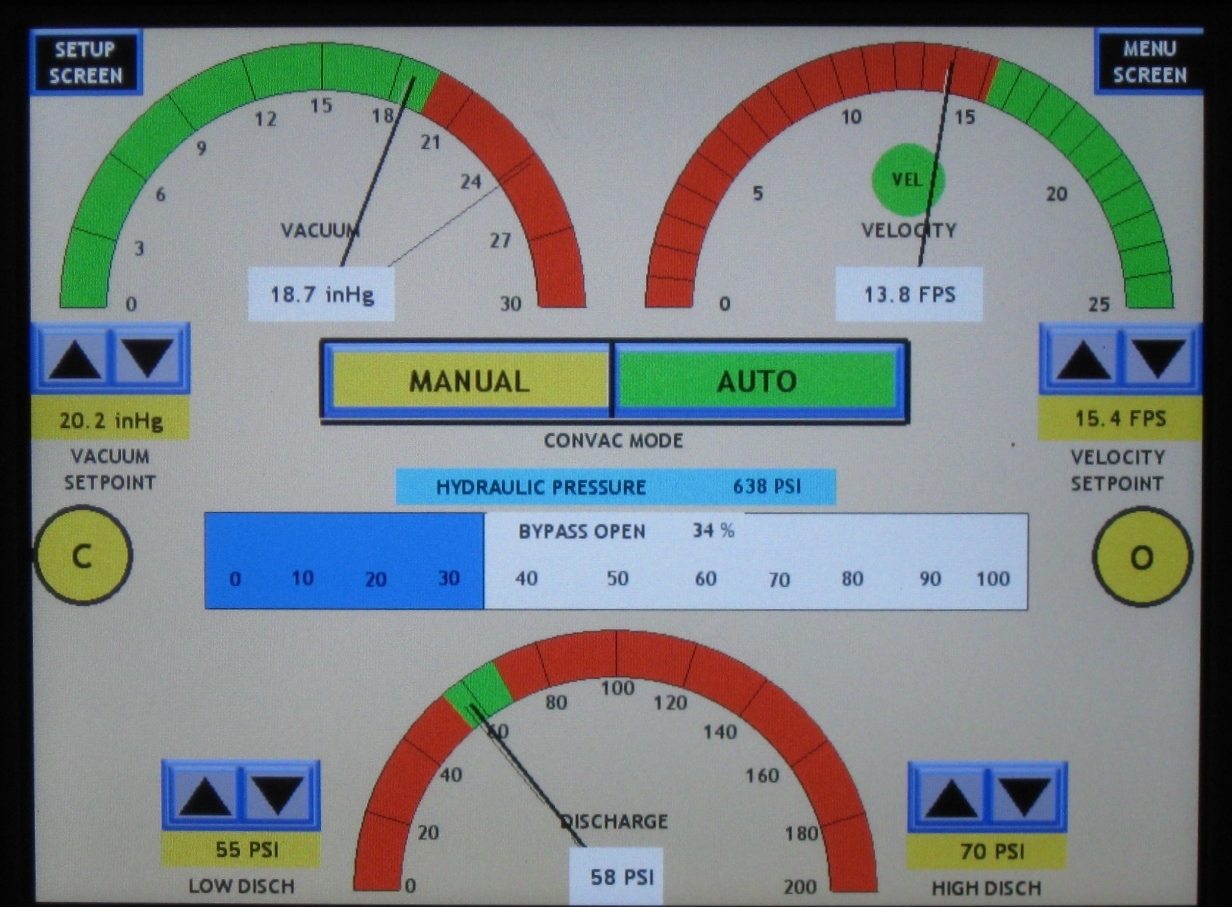

CONVAC TOUCHSCREEN DISPLAY

CONVAC TOUCHSCREEN DISPLAY

FIGURE 2

NOTE; “Setpoint Velocity” and “Setpoint Vacuum” refer to the values to be entered in their respective boxes on the CONVAC touchscreen. See Figure 2.

Q10 What constitutes a CONVAC system?

A Major components;

-

-

- A customer-furnished and installed flanged bypass pipe that tees into the suction pipe near its inlet and extends far enough up the ladder to where the Linear Needle Valve will not be covered by cave-ins. See Figures 1, 5 & 6.

- A Twinkle Co Linear Needle Valve bolts to the flanged, open end of the bypass pipe. See Figures 1, 5 & 6.

- A Twinkle Co hydraulic power supply and control package. Taps into customer’s existing hydraulic system.

- A Twinkle Co remote touchscreen control and display panel. See Figure 2.

- An enclosure containing the electronic components and circuitry programmed to process inputs from various sensors, power the remote touchscreen and control the Linear Needle Valve.

-

Q11 What is the warranty on CONVAC?

A One year on all components.

All possible concern is given to making CONVAC as trouble-free as possible. Failing that, modular design, built-in diagnostics, phone consultation, overnight delivery and provision for DIY (Do-It-Yourself) parts installation makes for a speedy repair and minimal down time.

Q12 CONVAC seems expensive. How will I get my money back?

A Numerous are the ways;

1. Increased production. New CONVAC users always report substantial increases in solids production; 20 to 40% on average! Such increases enable the cost of a CONVAC system to be recouped in a very short time after which the increased production is all profit.

2. Increased sand-classifying tank efficiency. CONVAC users report that they get a notable increase in the yield of specification sand from their pits. This is because the efficiency of classifying tanks is VERY dependent on a steady, uninterrupted, consistent slurry inflow.

3. Happier dredge operators. CONVAC enables operators to be more productive with less effort. Vacuum control is virtually automatic and once-feared threats such as cave-ins, pipeline plugging, over-production and choke-offs are either minimized or eliminated. And best of all, they don’t spend all their time jockeying their suction about in the attempt to maintain a certain vacuum.

4. Reduced wear cost per ton produced. Pump and pipeline wear cost per ton decreases as the slurry density increases.

5. Increased dredge efficiency means reduced energy cost. It requires less horsepower per ton to pump at the optimum Setpoint Velocity.

Q13 What other instruments and controls are available?

A Twinkle Co instrument and control systems:

-

-

-

- HOWDEEP Display, mining depth indicator.

- VEECON pump speed control system.

- LCAP Linear Cutter Automation Package control system.

- INDICANT Display, pipeline slurry density indicator.

- HEADHAWK Display, immersed housing head pressure indicator.

- CROSSPOINT NEEDLE Display, velocity vs. vacuum.

- GPS mapping.

- Data logging.

- Remote access.

- Production calculation and display (Density meter required).

-

-

Q14 What makes CONVAC superior to other systems?

A We will number the ways;

1. CONVAC’s Linear Needle Valve is designed to be partially open at all times maintaining Setpoint Vacuum despite the necessarily constant presence of excess pumpable solids at the suction inlet. If sufficient solids are not available to maintain Setpoint Vacuum the rate of production will decrease.

Competitive valve providers maintain that maximum production is possible only when their bypass valves are closed. That describes a dredge that does not have a bypass valve. It is a prescription for less than mediocre production.

2. CONVAC utilizes Dredge Principles #1, #2 & #3 to afford the means to obtain continuous, regulated production. It follows that if production can be regulated, it can be adjusted to the maximum possible rate. There is no better way. Nothing else satisfies!

Competitive bypass valves operate without principles. They flop open as soon vacuum touches a setpoint and wander toward the closed position unless the vacuum pops up again to trigger a replay of the valve opening exercise. Such programming eliminates any possibility of “maximizing production.”

3. CONVAC-equipped dredge operators can relax and concentrate on maintaining an excess supply of pumpable solids at the suction inlet. It is time to crowd the cutter into the solids bank when the CONVAC needle valve approaches the closed position.

Competitive bypass valve system operators are just as busy and stressed out as they were before it was installed. They still have to jockey their suction inlets about in the attempt to increase vacuum when falls below a setpoint.

4. CONVAC monitors and indicates the actual, real-time position of the Linear Needle Valve. That data is used to assure that valve movement is appropriate—that it moves quickly and only to the extent necessary to maintain the Setpoint Vacuum value.

Competitive bypass valve systems, to my knowledge, sense and display only two valve position accurately, open and shut. Other positions are calculated guesses.

5. CONVAC’s Linear Needle Valve goes shut only when there are not enough solids available at the suction inlet to support production at its full, regulated rate.

Competitive bypass valve systems are mostly programmed to open in emergency situations, solve a problem and then shut as soon as possible. They attempt to limit, not control vacuum. They make no attempt to control either velocity or the rate of production.

6. CONVAC’s Linear Needle Valve bypass valve has superior hydraulic flow characteristics and linear function so the entry of water into the suction pipe with precision.

Competitive butterfly bypass valves feature obstructed, non linear flow. Their disks and shafts clutter the water passageway causing turbulence, disk flutter and excess head loss. They are not suitable for this service.

7. CONVAC’s Linear Needle Valve modulates to maintain Setpoint Vacuum while the suction inlet is continually immersed in a supply of excess pumpable solids.

Competitive bypass valve systems cannot cope with the situation whereby excess solids are constantly available at the suction inlet. That is because they cannot control the bypass valve opening with the precision necessary to maintain Setpoint Vacuum.

8. CONVAC’s Dynamic Setpoint Vacuum feature utilizes intuitive analysis and automatically makes most of the small Setpoint Vacuum adjustments required to maintain Setpoint Velocity.

Competitive bypass valve systems seem to work on the theory that the maximum rate of solids production will result if the operator is successful at maintaining a certain vacuum just so long as it remains below the value that will cause their valve to flop open. Assuming this difficult-to-meet goal is met, the rate of production will still be uncertain because a fixed vacuum is only a gross indicator of the rate at which solids enter the suction inlet. Velocity and pump speed are the definitive indicators of the rate at which solids flow through the dredge system.

9. CONVAC dampens the twitchy, jiggly pressure fluctuations normally found in the suction permiting only stable, accurate digital signals to enter its system software.

Competitive systems often suffer nuisance tripping when they rely on raw, vacillating vacuum readings. Frequent valve response to solve nonexistent problems is termed “nuisance tripping” and guarantees reduced production.

10. CONVAC enables the operator to maintain discharge pipeline flow at Setpoint Velocity by adjusting Setpoint Vacuum thereby insuring a constant rate of solids production if pump speed is held constant. With the means at hand to precisely maintain Setpoint Velocity the operator can incrementally increase or decrease it to ascertain the optimum velocity—the most productive flow rate.

Competitive bypass valve literature proclaims the capability to “maximizing” production. That’s a real hoot given their inability to regulate vacuum and total ignorance of the importance of velocity or pump speed control. Any claim to be able to “maximizing” production is preposterous.

SUMMARY

CONVAC is the only bypass valve system that guards against choke-off, over-production and pipeline plugging while controlling vacuum and making it possible for solids production to continue at full rate without interruption.

CONVAC enables rates of production unattainable competitive systems!

CONVAC has been putting extra profits in dredger’s pockets for over thirty years.

Practice safe dredging, always use a CONVAC!

LINEAR NEEDLE VALVE

LINEAR NEEDLE VALVE

Figure 5

CONVAC LINEAR NEEDLE VALVE ON BYPASS PIPE

CONVAC LINEAR NEEDLE VALVE ON BYPASS PIPE

Figure 6