Willard Says……

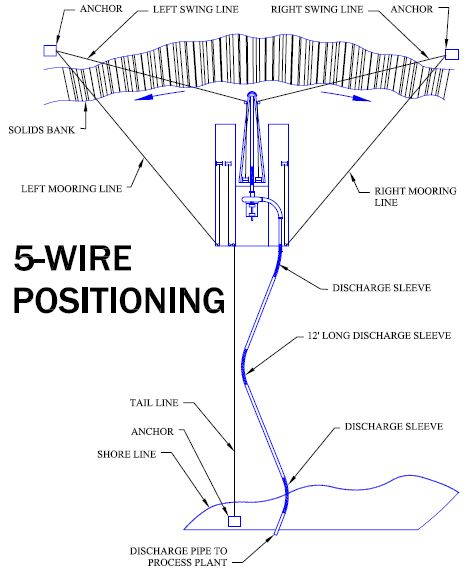

5- Wire Positioning is an enhanced version of the popular 3-Wire Positioning system. It should be used whenever the 3-Wire system cannot provide the maneuverability necessary to obtain good dredge production. See below for a sketch of this arrangement.

One or more of the following conditions may prevent the 3-Wire Positioning system from functioning effectively:

- High banks of material above the water surface.

- Deep digging depth.

- Shallow digging depth.

- Steep face of material caused by a bank that does not cave readily.

- High wind conditions.

- Fast current conditions.

- Tough digging conditions.

The 5-Wire positioning system will solve these problems.

The 5-Wire system is a 3-Wire system with the mooring lines from two additional winches reeved through sheaves located at the rear corners of the dredge and connected to either the swing line anchors or separate anchors. The mooring line winches should not be located on the rear end of the dredge. Note in the sketch that all the winches are located in such a way that the winch drums have the required “fleet angle”. This assures that the cable will wind onto the drum properly.

By adjusting the mooring and swing lines, the dredge can be swung in an arc about the tail line anchor. All winches should located so as to be visible from the operator’s cab. This allows the operator to see the length of cable being played out or taken in to position the dredge.

The three lines: two mooring and one tail, fix the location of the rear end of the dredge so the cutter is held against the solids bank. The only function of the swing lines in the 5-Wire system is to crowd the cutter basket sideways into the material. The swing lines no longer have to be arranged so that they will hold the cutter in the cut.

The tensioned

swing line may be pulling upward at a steep angle; however, this

will be countered by the weight

of the cutterhead and ladder structure. The slack-side swing line should be

tensioned sufficiently to keep

it from tangling in the

cutterhead without causing any lifting

force on the cutterhead.

The recommended operating procedure for 5-Wire positioning is the same as for the 3-Wire system with the additional requirement for periodic adjustment of the mooring lines. These lines must be adjusted as necessary to move the pivot point at the rear of the dredge in an arc along the face of material as dredging proceeds.

Dredge advances are made by playing out tail line and taking in one or both mooring lines.

The 5-Wire system detailed in this paper is an adaptation of the once-popular “Christmas Tree,” 5-Wire systems that I saw frequently in times past. Several dredge manufacturers featured a “Christmas Tree” arrangement where three winches were arrayed around a cluster of sheave blocks at the rear of the dredge hull. The blocks routed the three cables down over the rear end of the hull to three swiveled sheave blocks mounted on a strut located 7 or 8 feet underwater. The cables radiated out from the Christmas tree to two anchors forward of the dredge and one to the rear.

The location of the winches caused problems that led to the demise of many Christmas Tree positioning systems. Cable often snarled on the winches because they did not have sufficient fleet angle and they were located where the operator could not see them. Often these failings led to horrendous snarls of cable on the winch drums and users quit using the system. In addition to snarled cable, the Christmas Tree had another other serious flaw. Depending on the height of the material bank, the location of the forward anchors and the length of the strut, the forward cables sometimes sawed a hole in the bottom of the flotation.

The modern 5-Wire system prevents the problems associated with Christmas Trees so all the advantages gained by use 5 positioning wires can be enjoyed without the penalties of old.

Comment, question, criticism, information on products mentioned? Contact willard@willardsays.com