A system that helps underwater shaft seals do their job.

Willard Says……

Ladderpump shaft housings and and cutterdrive gearboxes function reliably only as long as the lubricating oil contained within them does not escape or become contaminated by intruding water. The key to keeping water out of submerged housings is to maintain a positive differential pressure across the shaft seal.

Other Willardsays papers—Willard Says...Shaft Seals and Willard Says…Static Head Tanks have dealt with various aspects of how to keep water out of submerged housings.

With the correct seals installed, the solution to the leakage problem becomes that of maintaining a positive differential pressure across the shaft seals. A static head tank may do the job at relatively shallow depths—less than fifty feet, a Dynamic Head Tank assures positive internal pressure in a housing at any depth.

The Dynamic Head Tank is the solution for those who find water in their underwater housings or dredge at depths greater than fifty feet.

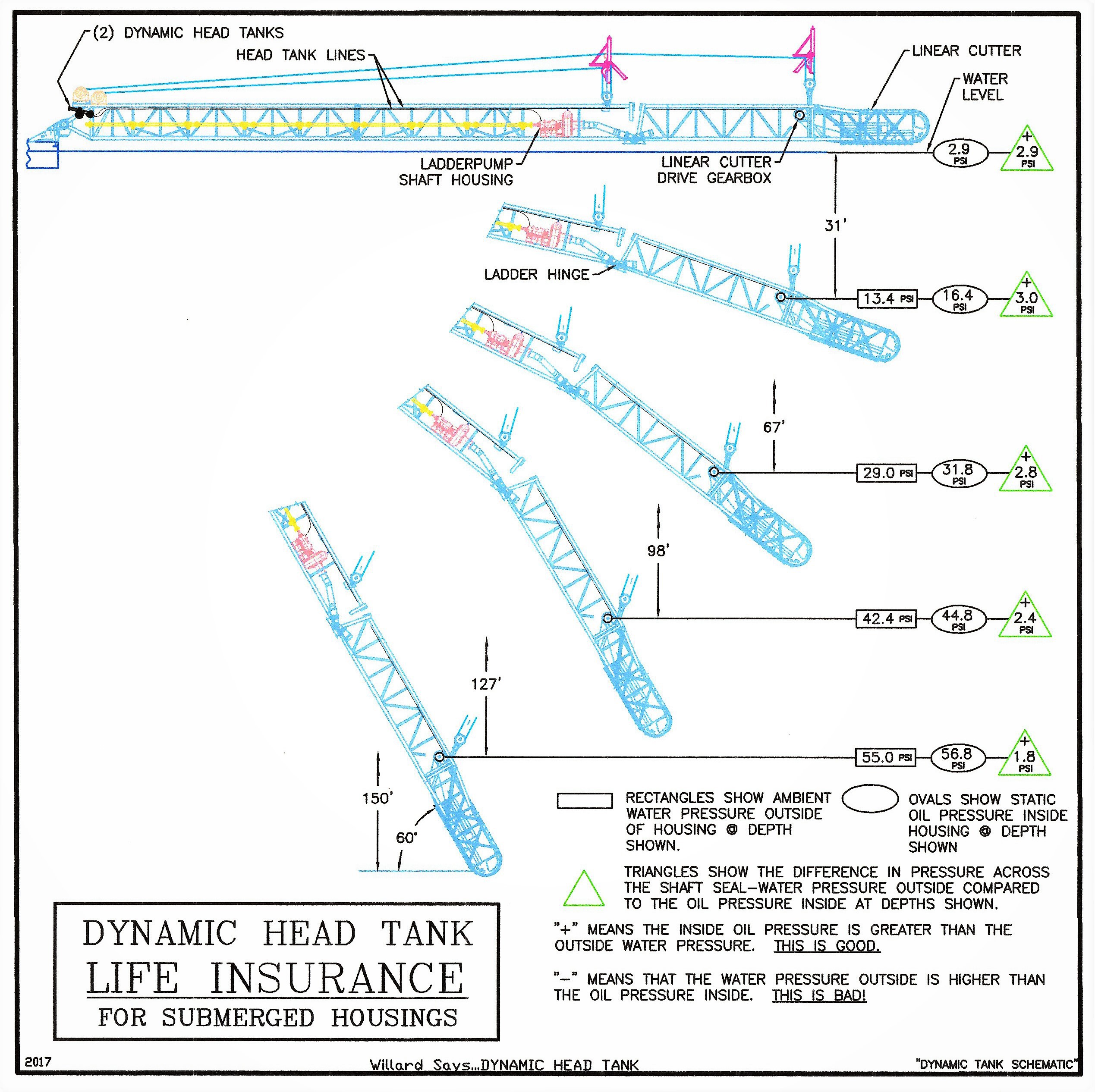

Figure #1 depicts a Twinkle Co Pelican Series dredge fitted out to mine to a depth of 150 feet with a Linear Cutter. The two-piece ladder is hinged near the midpoint and supported by tandem hoists. The hinge relieves the ladder frame of extreme stresses that could occur were the 182-foot structure to be all one piece. Also the twin hoists enable the loads to be equitably apportioned to the supporting pontoons. As of this writing this dredge has accumulated over 1500 hours of very satisfactory operation averaging 600 tons per hour.

As depicted, the dredge ladder is shown lowered in 15 degree increments. The pressures noted at each position documents how a Dynamic Head Tank functions to maintain a positive differential pressure across shaft seals regardless of depth.

It should be noted that attempting to use a static head tank to create a positive differential of 1.8 psi at maximum depth would require a tank height of 19 feet above water. Looking at the dredge you might think to mount the head tank on the hoist frame and the solution is at hand. Aside from issues of access and visibility, mounting the static head tank on the hoist frame results in extremely long pipe/hose runs. Getting ALL of the air out of the long lines would be a challenge. ANY air left in the lines would negate the advantage gained by raising the tank. Using a Dynamic Head Tank is the simple and sure solution. For complete peace of mind install a Twinkle Co HEADHAWK system to measure the pressure and be certain that a positive differential is maintained.

Refer to Figure #1

![]() Oval boxes show the housing interior pressure created by a solid column of oil at each depth plus the pressure imposed by the Dynamic Head Tank.

Oval boxes show the housing interior pressure created by a solid column of oil at each depth plus the pressure imposed by the Dynamic Head Tank.

![]() Rectangular boxes show the water pressure at each depth.

Rectangular boxes show the water pressure at each depth.

![]() Triangle boxes show the differential pressure between oil and water at each depth. The Dynamic Head Tank maintains a positive differential pressure at all depths.

Triangle boxes show the differential pressure between oil and water at each depth. The Dynamic Head Tank maintains a positive differential pressure at all depths.

Figure #1 The ambient water pressures shown in the rectangular boxes are calculated by dividing the depth, 31 ft for example, by 2.31 ft/psi to determine the water pressure at that depth. 31 ft/2.31 ft/psi = 13.4 psi. 2.31 ft is the height of a column of water that creates a pressure of 1 psi at its base.

Oval boxes show the oil pressure in the housing at the various depths. It is the sum of the pressure created by the height of the column of oil plus the pressure imposed by the Dynamic Head Tank.

Triangle boxes show the positive differential pressures that are maintained across the shaft seal at various depths. In all cases the interior oil pressure is greater than the water pressure on the exterior of the housing.

The theory is that when a positive differential pressure exists, leakage, if it occurs, will result in oil leaking out of the housing instead of water leaking in thus preserving oil lubricity. Signs of an oil leak would include a surface slick and a lowering head tank oil level.

Figure #2 shows an up and horizontal dredge ladder with a Dynamic Head Tank mounted aft of the hinge pin. The Dynamic Head Tank will incline with the ladder as it is lowered to operating depth.

Figure #3 is a photo of the Twinkle Co, ladderpump, diesel-powered, Linear Cutter equipped dredge depicted in Figure #1.

Hopefully, the first sign that lubrication has been compromised is not dredge shutdown due to component destruction caused by water intrusion through a leaking shaft seal .

Twinkle Co’s Dynamic Head Tanks are available to assure positive differential pressure across shaft seals at all depths down to 250 feet.

The price for a Dynamic Head Tank system is only a fraction of what it costs to rebuild a ruined cutterdrive gearbox. The price for this system is but a pittance compared to what it costs to restore a pump shaft housing to full health.

Find out more about the Dynamic Head Tank system.

Contact willard@willardsays.com with questions, comment or criticism.